How to Power Server Cabinet PDUs from a UPS System

Uninterruptible power supplies are a fundamental part of the critical infrastructure and power circuits within a server room or data centre. As with any installation, it is important to map out and plan the power connections to ensure that there are enough connections and the right level of protection in place for the IT loads.

What is a Server Cabinet or Server Rack Frame?

A server rack or server cabinet as they are sometimes referred to, is a cabinet made to house 19inch rackmount devices horizontally. The 19inch width includes the ‘ear’s which attached using M6 cage nuts and bolts to the vertical struts of the cabinet. There are four struts, one in each corner.

Server cabinet heights are measured in ‘U’ where 1U measures 44.45mm or 1.75inches high. The vertical struts are sometimes are marked with the U height and have square-holes punched out to take the M6 cage nuts, three per 1U spacing.

An open frame rack has not sides or doors. There are 2-pillar frames used for telecommunications installations but the standard in a server room or data centre is 4-pillar frame with side panels (removable/lockable) with a choice of front and rear doors: toughened glass, mesh, perforated or steel doors.

A server rack or cabinet manufacturer will typically offer cabinets from 4U to 47U with 27-42U being the most commonly used in a sever room and 42-47U in a data centre. The standard outer width is 600mm but some rack suppliers offer 800mm. The larger width allows for side cabling.

Depth of racks is important and can be 400mm to 1200mm deep. 400-600mm is fairly standard for wall mounted data cabinets with 600-1000 or even 1200mm for server and data centre cabinets. It is important to remember that this depth is the overall cabinet depth. Inside the usable depth is less as the vertical struts are set inside the overall depth.

Choosing the right cabinet depth is important for the equipment to be housed within the cabinet and deciding how it will connect to the frame. Small 100-200mm rackmount devices may only need to connect to the front vertical struts. Larger depths and heavier items may require connection to front and back struts. This is normally achieved using slide rails which are attached to the struts onto which the rackmount device is placed. The front struts take the ‘ear’s to secure the devices in place. Where rackmount is not possible, shelves can be used which can be installed inside a server cabinet, in the same way as slide rails. Shelving types include modem, fixed, heavy duty and telescopic.

When planning a server rack installation are simple method is to use a Microsoft Excel spreadsheet o CAD drawing package to ‘map out’ where each IT device is to go inside the server cabinet. This should take into account bottom or top cable entry and ease of access and any installation prerequisites. For example, UPS systems are generally placed in the bottom of a server rack so as not to affect the centre of gravity and keep the UPS away from potential ‘hot-spots’.

What are Power Distribution Units?

Power distribution units are PDUs that have output sockets (referred to as outlets) and a power cord or lead which is connected to a UPS system or local supply. The output sockets are of a fixed number and rating and can include C13, C19, BS1363 UK square-pin and Schuko. PDUs can be basic, offering power only, metered at the PDU, metered at the outlet and intelligent with SNMP interface connections. Single and three-phase power PDUs are available.

Small 6-8 outlet PDUs may mount horizontally on either the front or the rear of the cabinet pillars. PDUs do however tend to be vertically mounted on one of the cabinet’s rear struts. If there are A and B supplies, then two PDUs will be used, with one on each vertical strut. The PDUs are supplied with ‘ears’ and attach to the struts using M6 cage nuts and bolts.

Planning out where each device will go within the server rack or cabinet also allows for the critical power path planning and how many outlet sockets will be required. The total load can also be calculated, and network cable interfaces provided for managed PDUs and remote communications.

Generally the output sockets in a single phase PDU will be one or more of the following types:

- C13 / 10A rated

- C19 / 16A rated

- BS1363 square pin (UK) 13A rated

- Schuko (European) 16A rated

The amperage ratings are at 230Vac, 50Hz – the harmonized voltage in the UK and Europe for a single-phase power supply. Combination outlet PDUs are popular where there are a mixture of load types to power. A typical example would be IT servers (C13-C14 power cords) and peripherals with their own AC/DC power supplies requiring either a C13-C14 power cord or a C13- BS1363 square pin plug for example. Outlets can also be off-set 90° to help cabinet cabling with PDUs available for right or left-side rack installation.

The incoming power supply to the PDUs also requires planning. The PDU may be powered directly from a UPS system or via a distribution panel arrangement.

Connecting Servers and IT Loads to a UPS System

Uninterruptible Power Supplies generally offer standard outlet connection options dependent upon their VA/kVA rating.

Typical UPS power connection arrangements include:

| UPS Size | Outlets (Qty x Type) | Typical Mains Power Connection |

|---|---|---|

| up to 2kVA UPS | IEC C13 outlets (10A) | IEC C14 power cord with mains power Plug |

| 3kVA UPS | 4xIEC C13 (10A) and 1xC19 outlets (16A) | IEC C20 power cord with mains power Plug / 16A Commando plug (blue) |

| 4-6kVA | Hardwired Input/Output terminals | Hardwired Input/Output terminals or Commando plug (32A) |

| 8-10kVA plus | Hardwired Input/Output terminals | Hardwired Input/Output terminals |

The table is representative of standby, line-interactive and online UPS (monobloc and modular).

In the UK, the standard plug will be a BS1363 square-pin style. The mains power supply should be suitably rated. Care should be taken when using a C20 power cord (3kVA UPS) as the uninterruptible power supply will draw up to 16A i.e. higher than a standard wall socket. In this scenario, the PDU requires a power cord and plug to match the UPS output connection. For example, a C14 for a UPS up to 2kVA and a C14 or C20 for a UPS up to 3kVA.

Where the UPS has an extended runtime battery, the UPS may have a larger charger installed or an extra charger is installed with the battery set. This will increase the load requirements. The UPS specification will state the max power drawn by the UPS system.

Plug-in UPS Maintenance Bypass Installations

A UPS maintenance bypass allows the uninterruptible power supply to be maintained and isolated for service without interruptible to the load. Up to 3kVA, the maintenance bypass will itself provide outlet sockets and can act as a small PDU or one of its outlets (C13) can be used to power a PDU. Wall mounted and 19inch rackmount UPS maintenance bypasses are available.

Hardwired Uninterruptible Power Supply Installations

If the uninterruptible power supply is hardwired, the electrical installation and PDU connection will require electrical works by a suitably qualified electrical contractor/electrician. For hardwired UPS installations a hardwired UPS maintenance bypass is required. Again, the bypass allows the UPS to be safely isolated for maintenance without interruption to the connected loads.

The electrical power path will be similar to a plug-in installation but could also include a sub-distribution board if there are multiple PDUs to power i.e., multiple server racks protected by the UPS installation.

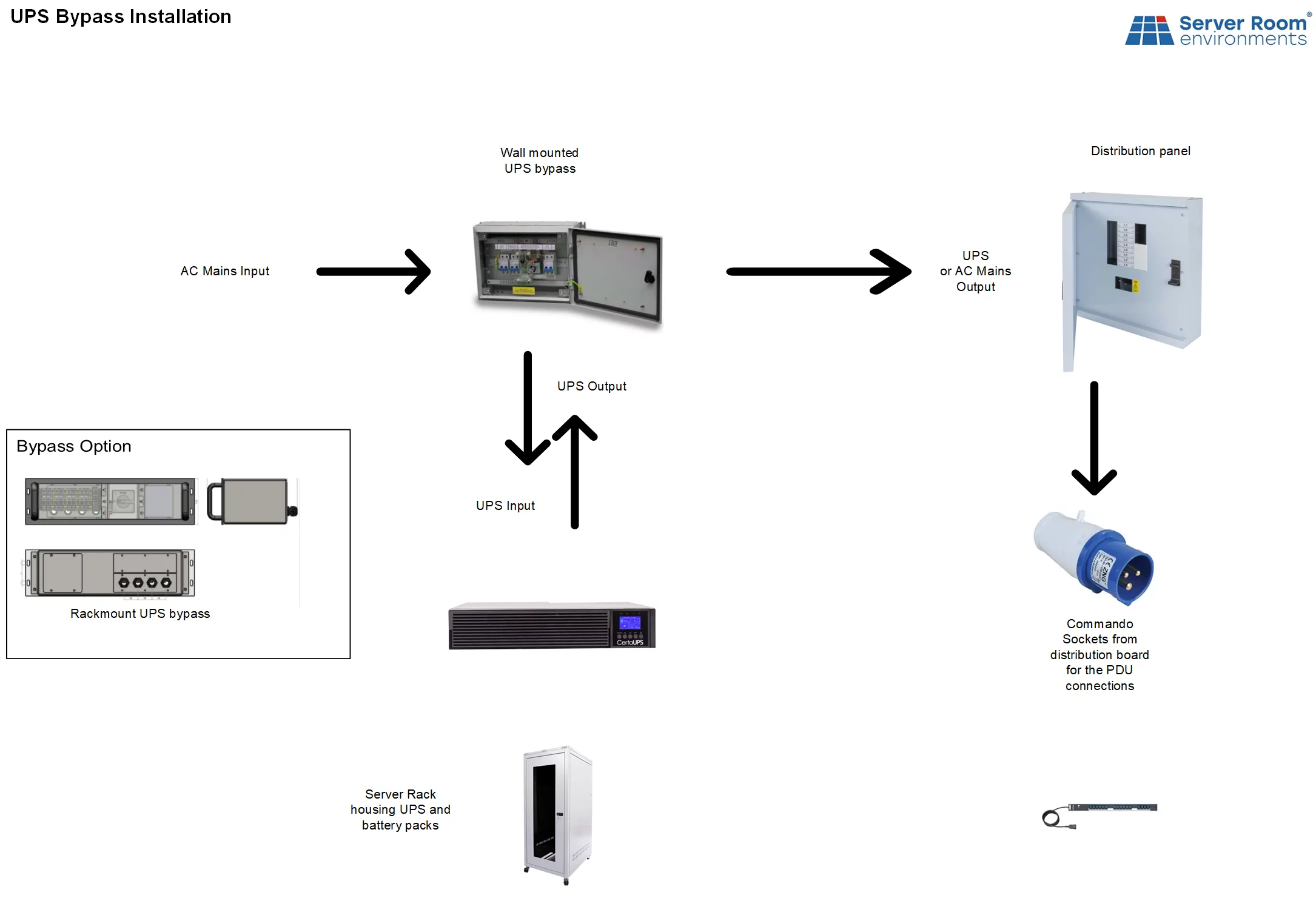

A typical arrangement is shown in the diagram below for a hardwired UPS powering multiple server racks and PDUs. The sub-distribution board is connected to the output of the UPS maintenance bypass and has one or more ways (individually protected by a circuit breaker) with an electrical hardwired to the board, but with a suitable socket outlet at the other end to which the PDU is connected. The power cord to supply the PDU may be run under a raised access floor or in overhead cable tray, dependent upon whether the server rack has bottom or top cable entry.

A UPS maintenance bypass is always recommended for IT server and network loads that cannot be interrupted without a planned power down, for UPS maintenance or isolation. With a UPS bypass installed, the installation will typically connected the rack mounted PDUs via a sub-distribution board. The board and upstream electrical supply should be suitably sized discrimination and allow for load expansion, if further server cabinets (and PDUs) are to be powered at a later date. For this reason, the sub-distribution board should have spare ways for connection to new loads.

Summary

Whether you have one or multiple loads to power from a UPS system, care has to be taken to ensure the UPS is suitably rated and that it has the correct type and size of outlet arrangement required to power the load directly or via some form of power distribution unit.

A UPS site survey is recommended for more complex UPS and PDU installations. This can also identify additional electrical works that may be required from an ECA approved electrical contactor (https://www.eca.co.uk/) including cabling routes and a review of the electrical supplies available, including their rating and suitability for the UPS installation.

Whilst smaller server rooms tend to have single-phase mains power supplies, larger facilities and data centres will generally have a three-phase mains supply to care for the load sizes. The same planning principles apply in terms of identifying the load and power connections, UPS sizing and electrical works required, which may also including consideration for a standby power generator.