How Humidity Levels Affect Server Operations

It is difficult to predict the British weather at the best of times. Over the last year we have seen extreme changes within days, from high temperature heat waves to torrential downpours. For anyone running and IT facilities, these weather patterns create additional demands on local cooling, temperature and humidity level management systems.

Heat Load and Humidity Levels

When most people think about the environmental management aspects of a computer room or datacentre, they think about how to manage the heat load. Servers and storage devices kick out a lot of heat and within some racks the power usage and therefore heat load can be anything from 3-15kW or more.

A less explained threat is that of humidity within these IT environments. The ideal relative humidity (rH) for a server room is between 40-60%. When humidity levels are too low, static electricity can build up. The air is basically too dry and electrostatic discharge can build and then be discharged when earthed to ground.In a typical 20% relative humidity environment, static can build quickly up to damaging levels (up to 35,000volts) as people walk along ungrounded raised access floors or synthetic carpet times. At 80% relative humidity the static voltages are far lower (250-1200volts). At higher humidity levels the cool air leaving an air conditioning system can lead to moisture build-up on hot metal surfaces, which can then drip and ‘pool’ as gravity draws the moisture downwards.

We have all experienced high humidity and no more so than after a few very-hot days in the UK, which are almost always followed by a thunder and lightning storm. In a server or computer room environment, high humidity can lead to moisture (air water content) from the air accumulating, leading in the long term to corrosion and potential equipment failure.

In the short-term electrical short-circuits can result. The nett effect of high humidity is a potential for system down time and even an electrical fire.

For more information see ANSI/ASHRAE Standard 90.4-2019, Energy Standard for Data Centers

https://www.ashrae.org/news/hvacrindustry/2019-update-to-standard-90-4

Air Quality Monitoring

Almost all IT environments are areas in which people are expected to visit and work; IT, electrical & mechanical and facilities engineers being just three of the most common. From an optimum health point of view 40-60% is also the ideal relative humidity range for anyone working within the area including workshop and office areas.

High humidity levels reduce air quality. When the relative humidity is too high, people with respiratory conditions can suffer difficulties. A highly humid environment can also provide a per perfect atmosphere for the bacteria, fungus, mildew, mould, and microorganisms to grow.

An unpleasant ‘mould’ smell being the most obvious sign with others including black patches, often in hard to read areas behind racks, on ceilings and around air ventilation and cooling vents. Such issues can affect the health of employees and be a major issue for organisations with longer-term high humidity levels to manage, especially in tropical areas.

Moisture Level Detection

There are several ways to detect humidity and moisture levels. The recommenced best practice approach is to use a combination of sensors with an environment monitoring device.

- Temperature & Humidity Sensors: a combined sensor can be connected to a monitoring device to detect for high levels of temperature and humidity. This is a slightly more sophisticated and therefore expensive sensor than a temperature only one, but the benefits are that the combined sensor only takes up one port on the environment monitoring device.

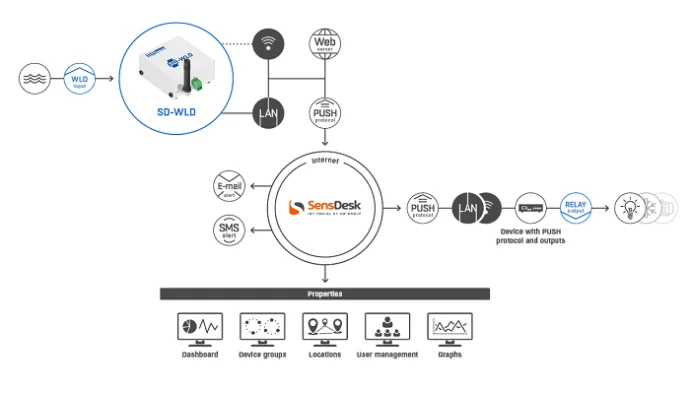

- Water Leakage Detectors: water leak detection devices have a monitoring cable (which can run from 2 to 85m or more), which is connected to a water leak data collector. The cable is extremely sensitive to not just liquids but droplets including moisture.

With either method, the sensors and detectors will initiate alarm conditions when high levels of moisture are detected. The alarms can be over an Ethernet/IP local area network or reported to a Cloud-based monitoring portal.

Other Humidity Level Monitoring Projects

Whilst server room and datacentre environments are the most obvious areas for humidity and moisture level monitoring, there are others. These include:

- Retail and Food Distribution: food, clothing and retail good packaging can be damaged by high moisture content, and especially when in storage for long periods in time i.e. shipment containers (air, sea and road). The ideal relative humidity level is far lower than a server environment at around 15%.

- Pharmaceuticals and Chemicals: product integrity is a key aspect within these industries and can be quickly eroded by humidity levels rising too high or low, during production, transportation or storage.

- Manufacturing Environments: in any form, whether electrical, electronic, metalwork, paper or plastic should be monitored for humidity levels. In tropical countries, monitoring and management of humid conditions is the norm but within the UK and Europe, shifting weather patterns can present new problems for manufacturing companies to manage.

For any of these and other related applications, humidity and water leakage monitoring becomes an extension of the local and wide area IT network. Specific sensors and environment monitoring devices can be installed and connected (hardwired or wireless) to a local Ethernet/LAN or Cloud-based environment monitoring software platforms. Where the ideal humidity level is 40-60%, this could be considered a safe measurement range with alerts issued when the monitored humidity levels reach either 30 or 70%.

Summary

An unplanned for change in a room’s temperature can indicate problems or failure of the local air conditioning system. In a server environment this can be potentially disastrous, and most organisations now monitor their server room temperatures.

However, sudden temperature changes may not be the first available signal that there is an impeding problem for an IT environment. Changing moisture levels can indicate that the air conditioning system is set incorrectly (in normal or dry-mode) or that there is a local leakage into the IT space (plumbing leak, poor door or window sealant or fault under a raised access floor).

Whilst a temperature change can be sudden, humidity and moisture levels can rise slowly over longer periods. These changes provide an opportunity window for local or subcontract engineers to address the problems before they become critical and downtime becomes inevitable.