How to Monitor UPS Battery Systems

Batteries are one of the most expensive consumables in an AC or DC uninterruptible power supply and so it makes sense to protect your investment as best you can. Whilst most UPS systems will test their overall battery health, sometimes the testing is not extensive enough to identify individual battery blocks within a battery string that can be close to failure or have an internal fault.

UPS Battery Faults

The manufacturing process for lead acid batteries is well-established, and using a leading brand battery such as YUASA, Enersys, FIAMM or CSB Batteries using means that you have a very reliable battery set. The early life failure rate for batteries from these manufacturers are rare and will typically follow a bath-tub curve.

Energy storage and the charge/discharge process in a lead acid battery is a chemical process reaction and one that is temperature sensitive. Even when not used a battery will self-discharge and care has to be taken to ensure that batteries are not left without a charging system in place for longer than 6months; the benchmark for lead acid batteries left in storage.

What Is the Ideal Operating Temperature for UPS Lead Acid Batteries

Lead acid battery efficiency is sensitive to temperatures. The ideal operating temperature is 18-25°C. As the ambient temperature rises, the chemical reaction in the batteries speeds up. Whilst this can improve battery performance, lifetime ageing also accelerates. For every 1degree rise above 30, the design life halves.

For a 5year design life gel-based electrolyte battery this means replacement will be required in years 3-4 and for a 10year design life battery, years 7-8. As well as temperature affecting battery efficiency, other issues can result from operating at higher than recommended temperatures. These include potentially ground/earth and shorting of individual battery cells/blocks. A worse-case scenario being thermal runaway.

If the internal battery temperature remains high for too long, permanent damage to the chemical electrolyte can take place. This results in not only a reduce operating life but also the number of charge/discharge cycles the battery can undertake. At low temperatures, the internal chemical reaction slows down. Internal resistance increases, efficiency drops and the battery is not as able to provide high current on-demand i.e. during a power outage when battery backup is required. Extremely low temperatures can lead to a ‘freezing’ of the electrolyte in ‘wet’ batteries.

UPS Battery Systems

When a UPS system is installed, the batteries may be internal to the UPS or installed in an external battery cabinet or open or cladded stand. Batteries inside the main UPS cabinet will be monitored for temperature automatically. The UPS electronics include a temperature monitoring circuit.

For external batteries, additional temperature monitoring should be installed to ensure battery health and its capacity to deliver energy and runtime when required; during a power outage. UPS battery monitoring can also help to protect the battery set from temperature-related damage, extend the operating lifetime, and even reduce replacement costs. When a UPS battery set has to be supplied outside of the main UPS cabinet, this means that the battery is sized for a long runtime and/or a large UPS system. Its size and cost is therefore a large part of the overall UPS system capital cost.

If battery block temperature is not monitored, permanent damage can occur. Excess heat build-up will not only affect battery efficiency, but can result in the mechanical distortion of the battery case (usually a high-grade plastic), which can result in leakage of the electrolyte. A poorly maintained battery can rupture and present a chemical or fire risk.

How to Monitor UPS Battery Temperatures

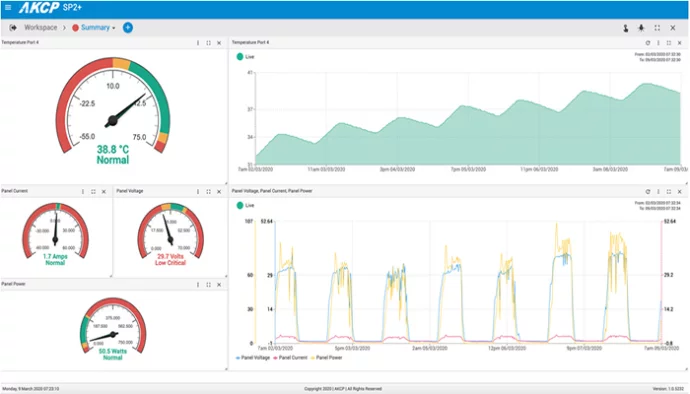

Battery temperature monitoring requires a sensor or set of sensors through which analogue data measurements can be taken. The sensors plug into a suitable environmental monitoring base unit (AKCP SensorProbe+ SPX8), that then reports the data to a monitoring platform. If the data varies outside of a chosen range, the environmental monitoring unit and software platform will send alert messages to a distribution list of email addresses. If the environmental monitoring system has a built-in or connected modem, SMS messages can also be set to a define mobile phone number list. Alternatively, an email to SMS service can be used.

A battery monitoring temperature sensor is typically applied to the negative terminal of a battery block. Under normally charging and load conditions, the temperature at the terminal should not rise by more than 3°C. A second temperature sensor is deployed to monitor the ambient temperature. The difference between the two sensors can then be used to monitor for potential battery health issues and/or failures in the attached blocks.

What is Thermal Runaway and How Does This Affect UPS Batteries?

Thermal runaway is most commonly associated with lithium-ion UPS batteries. Lithium when exposed to air/oxygen ignites and burns until all the stored energy is transformed into heat and noise, for example. News reports of electric vehicles (EVs) and mobile phone batteries are case examples, where a lithium battery has caught fire.

UPS with lithium-ion UPS are available but care has to be taken when these are installed in a server room or data centre environment. Fire suppression will only help to reduce the danger to the facility should a lithium-ion battery ignite. Lead acid UPS batteries are not as flammable and can be supplied with flame retardant cases meeting UL94 V0 / UL1778.

Lead acid batteries are exothermic during charging. This means that heat generated by the internal chemical reaction. Normally the heat is dissipated through the battery and via its plastic case. The batteries are endothermic during discharge, meaning that the battery materials absorb heat. Internal resistance (impedance) increases over the operating life of a battery, lead to increased heat generation and absorption.

Thermal runway occurs when a chemical reaction cannot dissipate energy/heat faster than the reaction or away from a reaction ‘hot spot’. A chain reaction occurs, increasing electrolyte and internal assembly temperatures. Explosive/toxic gases can be vented and a fire occur. The plastic cases used in valve regulated lead acid (VRLA) UPS batteries can melt if the temperatures rise too high; typically, at 160°C.

More information on Lithium-ion UPS in Data Centres

https://www.datacenterdynamics.com/en/opinions/data-center-ups-how-to-make-li-ion-the-safe-choice/

https://www.techerati.com/news-hub/kakao-data-centre-fire-lithium-ion-batteries/

UPS Temperature Compensating Charging Circuits

Modern UPS designs incorporate many features to help to protect their connected battery sets. One is the usage of automated temperature compensated charging. This adjust the ‘pace’ at which the connected battery is charged to optimise its performance and lifespan. As the ambient temperature increases, the rate of charge applied, is automatically reduced. The configuration of the charging circuit should be such that under charging is avoided to present sulfation build-up. Sulfation as with impedance, can result in reduced battery performance and increased ageing. Handheld battery testers can be used to monitor both impedance and sulfation on an individual battery block basis.

Battery Voltage Monitoring

Monitoring the DC power circuit provides another way to monitor the health of an individual battery block or a battery set. Typical examples include uninterruptible power supplies, generator starter-motor batteries and energy storage usage with solar PV systems.

A battery health monitoring sensor (connected to a suitable environmental monitoring system) can monitor for voltage, temperature and the current load placed on the batteries.

In a standby generator, supporting a data centre or server room UPS system, the sensor can identify trends in battery health and potential problems that could prevent the battery from powering the starter-circuit. Poor generator battery health can also indicate problems with the generator alternator circuit.

In a solar PV installation, a battery health sensor can be used to monitor the voltage and current output from the solar PV panels. A low DC voltage could indicate a need to clean the PV panels. When these are dirty (grime, dust, bird debris etc), their photovoltaic reaction efficiency is reduced. A battery health sensor can also monitor the output voltage and current from a connected energy storage system and its battery temperature. Comparing the battery current and the solar panel charging load measurements, can provide an indication as to the health of the overall energy generation and storage system.

UPS Battery Inspection 10 Point Checklist

Batteries do contain hazardous DC voltages that can cause harm if not handled correctly. Any battery inspection, testing or maintenance should only be carried out by engineers trained to work with DC power voltages. During a UPS maintenance visit, a procedure for battery inspection would include:

- Complete a risk assessment and method statement for the installation, if required

- Inspect historial records and the data collected via the environmental montioring system, if installed

- Ensure there is sufficient lighting and access to the batteries in order to carry out the inspection

- Isolate the batteries from the connected systems if appropriate or required

- Inspect the batteries and terminals for electrolyte residue, corrosion or wear & tear

- Check battery cases for swelling, cracks or leaks including chemical residue

- Check that all inter-cell and connection cable connections & terminals are tight (not loose)

- Check the electrolyte levels for each battery block if possible (Wet batteries)

- Record the room ambient temperature near to the battery pack position

- Record the results of the inspection and testing, noting any corrective or preventative actions

Any DC battery pack should have restricted access, with signage to warn of the dangerous voltage(s) present.

Summary

Batteries, whether used in an uninterruptible power supply, solar energy storage system or standby generator starter circuit will age over time. The speed of the ageing and overall efficiency is affected by several factors include the number of charge/discharge cycles they are exposed to and their ambient and internal temperatures.

Most server rooms and data centres have environmental monitoring for temperature, humidity, and water leakage. For a correctly sized base unit, additional sensors can be connected for battery temperature (negative terminal), battery ambient temperature (by the battery set or inside the battery cabinet), and the battery voltage and current can also be monitored. For any of these parameters (temperature, current or voltage) results outside of an acceptable range, can lead to automated alerts (emails and SMS text messages) allowing corrective actions to be take in a timely manner. Potentially preventing downtime and ensuring that the UPS and generator can provide backup power during a power outage.