How to Monitor Server Room Temperature and Humidity Levels

Climate change is driving up ambient temperatures and causing extreme weather patterns. For server room and datacentre operators, these environmental issues are placing a greater strain on their critical infrastructure systems. Server room air conditioning systems are placed under greater load during heatwave conditions and UPS systems must use their battery power more often to cover small power outages and complete mains power failures.

Most server rooms will have some form of uninterruptible power and an air conditioning system, but few will have a 24/7 environment monitoring system installed. Instead these smaller sites will rely on audible alarms being heard and someone being on-site. Not always possible after hours or at weekends and this is often the time when problems can and do occur.

The Role of a Server Room Air Conditioner

Air conditioners are sometimes referred to as ‘heat-pumps’. A wall or ceiling mounted air conditioner pump heat away from the room in which they are installed to an outside condenser. The room-installed AC unit and the outside condenser form a complete refrigeration system.

The need for air conditioning within a server room or datacentre environment arises from the high amounts of heat generated by the IT servers. Within a server rack 3-5kW of IT servers is common with larger systems rising to 10-15kW and even more for high density computing systems. Without cooling, the IT systems would overheat and there is the potential for a fire to start within the room.

The ideal temperature for a server room is around 18-25°. One or more AC units may be required to cool a server room to this range dependent upon the size and shape of the room and the heat load (amount of IT server kit). Air conditioners can also be arranged in an N+X configuration and it is common in critical application rooms to have two (N+1) AC units and for them to operate on a duty/standby cycling. Here one unit operates whilst the other is in standby or energy saving mode. This cycle is repeated weekly. Should one unit fail, the other can support the full heat load of the room.

Monitoring Air Conditioner Failures

Any air conditioner can be monitored to provide early indication of failure or a complete shutdown. More sophisticated AC units will provide remote monitoring via a plug-in SNMP card. This will allow the air conditioner to be given its own IP address on the local network and for the device to report alarms and problems over the network. Monitoring via SNMP allows the cooling system to connect into local data centre infrastructure management (DCIM) software and provide a range of temperature and performance related data.

An alternative to this is a plug-in volt-free signal contact card. This will provide what is termed as a ‘digital input’ or an ON/OFF state alarm to a monitoring system. The card may have one or more relays to identify issues: alarm condition or unit failed.

A correctly functioning air conditioner will provide a controlled temperature output, air flow and room humidity levels. These three issues can also be monitored using a room-level environment monitoring solution. A suitable environment monitoring device would have the ability to plug-in multiple sensors and detectors for analogue readings (e.g. temperature and humidity) and digital inputs (e.g. unit relays). Some monitoring devices also feature digital outputs, allowing the device to trigger an action by a third-party component such as opening an access-controlled server rack door.

Worst case, a server room air conditioner will have a font panel showing the temperature output and an LED status level. An LED should light ‘red’ when the unit has an alarm, blocked filter and/or require maintenance. The AC unit may also have an audible alarm. Monitoring an AC unit for alarms in this way is not recommended as there are issues in terms of ‘single points of failure’ i.e. who visits the room outside working hours and what process do they follow for recording that all is well with the unit?

The Role of an Uninterruptible Power Supply

Uninterruptible power supplies or UPS systems as they are also known, provide power to the critical IT server load. This is often referred to as ‘critical power’ or ‘back-up’ power. The UPS has internal batteries which provide a back-up runtime during a power outage or complete mains power supply failure. The amount of runtime provided is load and battery Ampere-hour (Ah) size related. Additional battery packs may be connected to the UPS systems for additional runtime. As well as providing back-up power, an uninterruptible power supply also provides a power quality function when mains or local standby generator power is present. The UPS filters spikes and electrical noise, smooths out sags, surges and brownouts and provides some protection from local lighting strikes.

Monitoring UPS Systems

The most critical component in a UPS system is the battery set, followed by fans and capacitors. All these items are classed as consumable components which will require regular inspection and maintenance. A UPS will test and monitor its batteries every 24hours. Any problems can be alerted by the UPS systems via an external connection.

UPS systems are like air conditioners in that they can be installed with an SNMP card and/or volt-free contacts card for remote monitoring. Their front panels also provide status information and a UPS will have an audible alarm. As with an air conditioning system ‘front panel’ or audible alarm monitoring is not recommended except as a secondary check to a remote monitoring system.

A room-level environment monitoring system can also be used to monitor the status of an uninterruptible power supply and power outages. Digital input connectors can be installed in the room and to the UPS and its battery system to provide signals to the central environment monitoring system installed.

The Advantages of an Environment Monitoring System

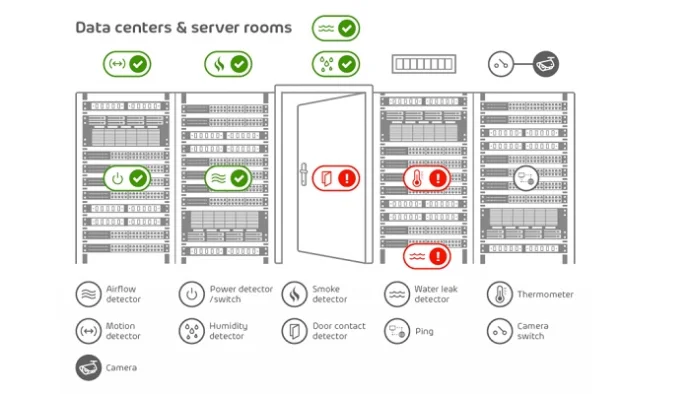

Critical power and cooling systems have built-in monitoring features and can report into a central DCIM monitoring platform. However, DCIM master station software is expensive and overkill for most server room facilities. A cost-effective alternative is an environment monitoring device which can monitor both room and rack-level and critical infrastructure systems.

- Room Ambient Temperature and Humidity: plug-in temperature or temperature and humidity sensors (or probes) can be connected to an environment monitoring system and are ideal for server rooms, datacentre and potential hot-zones within them including behind racks and in ‘hot-aisles’ to ensure an overall 18-25°C ambient.

- Rack Level Temperatures: monitor front panel air-intake and rear exhaust channel temperatures within a server rack at the bottom, middle and top i.e. 6-points per rack to ensure a 20°C difference.

- Water Leakage: with leakage detectors placed along the outside of the server room walls and under raised access floors in datacentres to detect for humidity build-up and/or potential water ingress.

- Air Conditioner Monitoring: using temperature, humidity and airflow sensors installed close to AC units to detect changes in performance or monitoring via signal contact cards installed inside the cooling systems for alarm conditions.

- UPS System and Battery Monitoring: monitoring power outages in the room using AC and DC connected sensors and/or picking up signal contact alarms from the uninterruptible power supply or separate battery monitoring system.

Depending on the feature-level of the environment monitoring system other plug-in sensors, probes and detectors can include door contacts, motion and vibration detectors, smoke and gas leakage, fuel and water tank levels.

Once an alarm condition is identified, the environment monitoring system can then report this via email or SMS text alerts over the local IP network or via a Cloud-based monitoring system.

For more information on Server Room and Datacentre Thermal Guidelines see:

https://tc0909.ashraetcs.org/documents/ASHRAE_TC0909_Power_White_Paper_22_June_2016_REVISED.pdf

Summary

Working patterns are shifting to allow remote operation and flexible working hours. Server rooms are expected to be operational 24/7 and yet for most organisations they are not monitored after hours or at weekends. If there are cooling or power issues, these may only be uncovered on a Monday morning or when someone reports a lack of IT service outside normal working hours. Furthermore, a critical cooling system failure can lead to a potential fire risk in the server room due to the rising power demands and server densities in racks.

Installing a room or rack-level environment monitoring system makes sense and many server room and small datacentre operators are now looking to install this type of system to their facilities. With prices from less than £200 for a server room monitoring device, the costs are also far from prohibitive, compared to server room or datacentre air conditioning and power system failures and unplanned for downtime.