How Data Centre Temperature Monitoring Prevents Downtime

Over 50% of all downtime in a server room or data centre can be prevented by monitoring temperatures. Hot temperatures not only damage electronics, leading to reduced mean time between failures MTBF) but are also an indication that a system is not performing as it should. The obvious example is air conditioning and cooling systems but electrical switchgear and UPS systems, can also generate more heat when there is an electrical issue. Hot spots can also occur within server cabinets, resulting from poor rack layout and cooling airflows, which can lead to potential fire risks.

The way to prevent temperature related data centre downtime is to use an environmental monitoring system with plug-in temperature related sensors. Furthermore, with the right system and sensors you can gather data to model temperature variations both inside and outside server cabinets.

Data Centre Temperature Monitoring Base Units

What matters most when you choose a temperature-sensing systems is the base-unit. This is the environmental monitoring device that connect to your IP-network and report the data. The reporting will either be to on-premises software from the device manufacturer or a cloud-based version. Avtech for example relies on its Room Alert software. AKCP is another leading monitoring systems supplier, who provide their AKCPro software, locally or via a cloud-based server. When selecting the base-unit, it is important to decide whether you want a rack mounted device or one that can be installed on a shelf or wall plate.

As important is to decide how many sensors you will need for the data centre environment, how far these will be from the base-unit and whether you then need to install multiple base-units on the IP-network to get coverage of the environment.

Most environmental monitoring systems will provide alarms via email or SNMP or other protocols including the industrial equipment protocol MODBUS. For SMS text alerts, you may have to consider an email-to-SMS service, if the base-unit does not offer a plug-in mobile SIM feature or additional network gateway device.

Data Centre Temperature Monitoring Sensors

The standard temperature sensor for monitoring temperature in a data centre or server room is a Digital Temperature sensor. Sensor variations can include plug-in cables that combine temperature and humidity and other environmental factors.

Avtech Room Alert Monitors can use a range of plug-in sensors including a Digital Temperature and Humidity Sensor that will monitor four environmental conditions including temperature, humidity, heat index and dew point. Heat index is sometimes referred to as the apparent temperature or how hot it actually feels. Dew point can be important is the temperature air must be cooled to become saturated with water vapour, assuming a constant air pressure and water content. Dew point and humidity levels are important within server rooms and data centres. Their air conditioners and cooling CRAC units control humidity. Too low and static electricity can build-up leading to a potential grounding and ‘electrical spark.’ Too high and water content can build-up on metal surfaces leading to corrosion, damp, mold build-up (in ceilings, under-floor areas and voids), and short-circuit risks.

Avtech Digital Temperature Sensors provide real-time temperature values from minus 55 to 125°C when used with a Room Alert environment monitor with an accuracy within +/- 2°C. The monitored temperature range is -55 to 125degC (-67 to 257°F) with a resolution to 0.0625°C.

The ACKP digital temperature sensors are available in NIST2 and NIST3 calibrated versions. A NIST Sensor has a traceable calibration certificate to standards set by the National Institute of Standards and Technology (NIST).

A 2 NIST certified, temperature sensor has a built-in calibration check. Each temperature sensing unit has 2x NIST calibrated and certified temperature sensors (acting as a pair). The primary sensor value is checked by the secondary sensor, and if the detected range is greater than the stated accuracy, an alert is generated that the sensor is out of calibration. This makes ACKP NIST2 sensors ideal for monitoring environments requiring a high degree of monitoring data accuracy and a calibration check.

3 NIST certified, calibrated temperature sensors are compared once a second for accuracy, with a backup, if the sensor is out of calibration. An AKCP NIST3 sensor has a built-in calibration check with calibrated sensors working in three pairs. The primary sensor value is checked by the secondary sensor, and if the detected range is greater than the stated accuracy, an alert is generated that the sensor is out of calibration. The sensor will then automatically failover to the next pair and continue monitoring with a seamless graph of data. AKCP NIST3 sensors are ideal for environments requiring a high accuracy, calibrated sensor with failover backup to ensure continuous monitoring of the critical environment.

For more information on NIST, see: https://www.nist.gov/

The monitored AKCP temperature sensor range is -55°C to +75°C, with an accuracy to within ±0.5°C accuracy from -10°C to +75°C. AKCP also supply temperature and humidity combination sensors. An advantage of a combined temperature and humidity sensor is that you save a plug-in monitoring port on your base-unit.

Other types of temperature-related sensors include:

- The Digital Active Power Sensor with Temperature. This monitors both power status (availability) and temperature and can be useful for monitoring HVAC equipment in server rooms and data centres as well as applications elsewhere in a building including pumps, refrigerators, freezers, and cold storage facilities. The sensor is non-intrusive and uses induction to monitor for power availability when attached to a power cable.

- Digital Temperature and Air Flow Sensors. This monitors both room ambient temperature as well as air flow from cooling fans, vents and even air conditioning systems and dehumidifiers in server rooms and data centres. The Avtech digital temperature and air flow sensor can also calculate the CFM (Cubic Feet per Minute) which is a measure of volume used to indicate the output rate of an air compressor in terms of cubic feet of air per minute of operation.

- Outdoor Temperature Sensors are designed for more extreme temperature variations and typically have external silicon coating to increase their resilience in harsh environments. Outdoor sensors can typically monitor to within +/- 2% accuracy for a range of -55 to 125°C.

- Fluid Temperature Sensors which can be used to monitor fluid temperatures including low freezing and high boiling points. Ideal for monitoring refrigerated, frozen or other cold-storage areas that may be used to store vaccines, medicines, and foods. A fluid sensor can typically monitor to within +/- 2% accuracy for a range of -55 to 125°C.

The more data you can gather, the greater the picture you can create of what is happening from an environmental monitoring point of view in your server room or data centres spaces, and their server cabinets. This is where the AKCP thermal cabinet maps and intelligent sensor products can provide greater visibility and predictive modelling to allow you to have greater control of your environment and IT operations.

AKCP Cabinet Thermal Maps

ACKP Cabinet Thermal Map Sensors can be used with the AKCP SPX8 sensorProbe+ to monitor temperature differentials between the front and rear of a server cabinet. The sensor can monitor temperature only or in dual format, temperature and humidity and helps to monitor and identify server cabinet hotspots.

Using thermal map sensors can help to identify airflow problem areas and obstructions within server racks. For example, cabling and other obstructions can impede the flow of cool and hot exhaust air leading to high-temperature differentials between the inlet and outlet temperatures.

Also, as fans age, they can fail and the airflow over the IT equipment will reduce leading to higher temperature differentials between front and rear of a server cabinet. AKCP Thermal Map Sensors can provide early indication of fan failure and problems with fan-related air flow.

When there is an insufficient pressure differential between the front and rear of the cabinet, airflow speed reduces. The less cold the air flowing through the cabinet, the higher the temperature differential front to rear will become.

AKCP Thermal Map Sensors can help to identify areas for investigation and provide alerts when temperatures fall outside an acceptable range. The thermal map sensors can also be used to provide the data required when adjustments are need to data centre cooling systems to improve Power Usage Effectiveness (PUE).

AKCP Data Centre Modelling

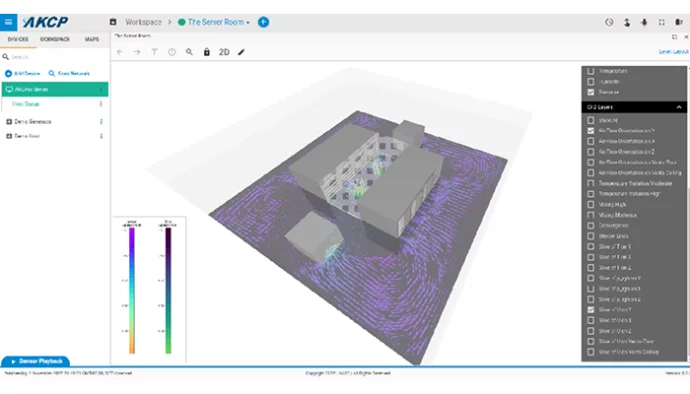

The AKCP modelling software allows data centre operators to optimise their cooling systems and save energy. Intelligent sensors can be used to model and predict airflow in a server room or data centre environment.

Data from AKCP sensors (installed onto the server cabinets and racks) is collated for the data centre monitoring tool to graphically model. Using the modelling software helps to reduce operating costs, avoid hot and cold air paths mixing, prevent over and under cooled areas of the data centre space, including hot and cold aisles and the server cabinets themselves.

With modelling software, sensor values can be added both manually and automatically in real-time from the installed AKCP sensors for each server cabinet or rack for the simulation to run. Using intelligent sensors can therefore produce an extremely accurate simulation and forecast of the air flow and cooling paths within the server room or data centre space. Automated alerts can also be set-up when recorded values move outside of pre-set bands.

Summary

Monitoring temperature and other environmental conditions in a server room or data centre is sometimes push lower down the build agenda compared to uninterruptible power supplies and computer room air conditioning systems. Environmental monitoring should however be viewed as a critical infrastructure system, and one that for a low-cost investment, could help to prevent downtime and keep your server room or data centre operational. Choosing the right environmental monitoring solution, that will allow provide sufficient sensor ports and digital inputs/outputs (DI/DO) is important, as is understanding the conditions that you want to monitor. Temperature being the most important within a server room or data centre environment.

For more information on data centre outages and their causes see: https://uptimeinstitute.com/data-center-outages-are-common-costly-and-preventable