A Guide To Data Centre Digital Twin Technologies

Large data centres typically use digital twin models to walk-through designs and compare planned to actual performance. Advances in digital twin modelling and the monitoring solutions behind them are making the technology more widely available. Especially for medium to smaller-sized data centres who in the future could also be required to provide more granular energy efficiency, renewables usage and low carbon reporting.

What Is A Digital Twin?

A digital twin is a 3D digital model of an planned or actual real-world product, system, process or facility that can be used for a range of purposes including simulations, integration, testing, monitoring, maintenance, load planning and capacity planning. Using a digital twin allows organisations, including data centres to compare a design to actual performance, identify issues and implement corrective measures and prevenative actions.

A data centre digital twin is a 3D model of the physical design and layout of your data centre which can be used to analyse cooling, airflow, energy, and power usage, identify potential performance improvements and model their outcomes. Using digital twin technology provides data centre operators and managers with a virtual tool to model, implement and monitor savings in operational running costs.

Within data centre environments, digital twin modelling has been expensive and out of the budget reach of many organisations. Advances in digital twin technology are now making the concept more readily available for medium to smaller-sized data centres who could also benefit from improved cooling and energy usage efficiencies.

This is important, as the world continues to warm and organisations face increasing economic and legislative pressures to reduce their energy costs and report on their usage.

Legislation for Data Center Energy Usage Reporting

An example are the changes being made to the European Union (EU) Energy Efficiency Directive (EED). Once approved, the changes will require enterprises (including data centres) with a consumption of more than 23,700 megawatt hours (MWh) per year to maintain an energy management system (EMS), perform periodic energy audits and report on their action plan and progress towards energy usage reduction objectives publicly. In addition, data centres facilities with over 500kW of installed IT equipment (based on rating plate values) must report operational data and metrics.

More information on data centre energy monitoring and regulation:

https://www.computerweekly.com/opinion/IT-Sustainability-Think-Tank-Green-IT-regulations-and-the-datacentre

In Germany, the government passed a draft of the Energy Efficiency Act in April 2023, with section 4 detailing energy efficiency requirements for new data centres. New facilities have to comply with new energy efficiency standards, ensure a minimum air cooling temperature and use the waste heat they generate. Existing facilities may be partially exempt from the new rules, but could be obliged to pay attention to their electricity use efficiency and increasingly use energy from renewable sources. Specifically, the draft stipulates that data centres commissioned before 1 July 2026 must be built to achieve a Power Usage Effectiveness (PUE) of 1.5 from 1 July 2027. The target PUE becomes 1.3 from 2030.

More information on energy efficency reporting:

https://www.pinsentmasons.com/out-law/news/uk-and-germany-energy-efficiency-rules-for-data-centres

In the UK, the Financial Conduct Authority (FCA) listing rules, now mandate a range of entities including asset owners and managers (investment portfolio managers, fund managers) to report on their climate-related risks. From April 2022, this was extended to include listed companies and large private businesses, including data centers.

More information on low carbon reporting for datacentres:

https://www.datacenterdynamics.com/en/opinions/carbon-reporting-legislation-pushes-uk-data-centers-to-go-green/

More legislation and reporting requirements are anticipated and these will lead to the need for more granular monitoring and data analysis within server room and data centre environments, and across building operations in general.

The 3 Key Benefits of Digital Twin Data Centres

Digital twin models can be used for any size server room or data centre. The technology provides several benefits and whilst the focus has been on large data centres and energy consumption, there is a growing demand for an easier to deploy and lower cost environmental monitoring and modelling solution that can be used within medium to smaller sized data centres and server room environments.

There are several benefits to creating a data centre digital twin for any size organisation. The 3 key benefits include:

- Improved Energy Efficiency and Power Usage: cooling can account for up to 40% of data centre’s energy spend. Digital twinning helps to identify areas for improvement and cooling optimisation. Wasted cooling and energy can be more easily identified. The impact of planned changes to make improvements or bring new server online can be modelled prior to deployment.

- Resilience and Uptime: a digital twin can help to identify potential problem areas and allows for proactive actions to address them. Cabinet thermal maps help to identify hot-spots and areas of poor cooling efficiency. Redundancy thresholds can be protected through proactive monitoring the server rack kW power loads. Actual load measurements help to ensure circuits are not overloaded and breaker thresholds reached within the critical power path including distribution panels, branch circuits and busways.

- Reduced Engineering Costs and Improved Productivity: using a software platform like AKCPro Server allows data centre managers to remotely monitor data centre performance and carry out predictive data analysis and digital twin modelling. The software provides actual performance data and displays in real-time, including automated alerts for data variations via email, SMS text and phone calls, and allows for instantaneous performance analysis. The sensor data can also be integrated into popular DCIM Packages via SNMP.

Traditional digital twin solutions can be unecessarily complex with costly implementation projects and costly annual fees.

The ACKP Digital Twin Solution for Intelligent Data

AKCP have developed digital twin tools as an extension to their enviromental monitoring system. This has created an easier to deploy solution that can scale for any size organisation and without expensive annual software and maintenance costs. The AKCP solution consists of three components:

- Environmental monitoring devices: such as the sensorProbeX+ for data concentration and reporting

- Intelligent sensors for data collection including airflow & temperature modelling software and cabinet thermal map sensors

- Digital Twin modelling software as part of the AKCPro Server software platform

Using the AKCP approach to digital twins, data centre managers can deploy a more cost-effective solution and realise some of the DCIM benefits associated with more costly packages.

AKCP Digital Twin Technologies for Data Centre Operators

To create data centre digital twins for any facility, you need to collect accurate, real-time data. Our projects team use the AKCP environmental monitoring system. This includes base monitoring devices, fixed cable and fsensowireless, and plug-in sensors that can be used to collect the data. Typical sensors used in digital twin models include cabinet thermal maps, power meters and water leakage sensors.

These sensors are used in server room and data centre environments to collect environmental data that is used to create alert notifications for temperature, humidity, water leakage, collect energy usage data and report on power related problems. The same data can be used to create a digital twin for a data centre.

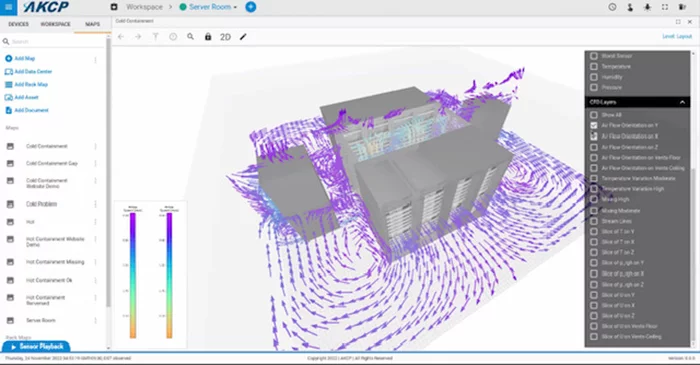

AKCP Data Centre Modelling Software

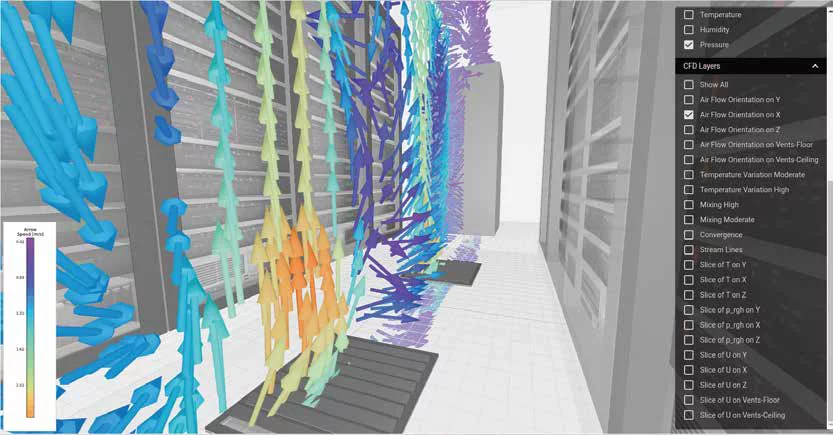

The modelling tool is part of the AKCPro Server software package, used in server rooms and data centres for environmental monitoring, data collection and alert notifications. The software provides real time insights to data center performance metrics including power usage effectiveness (PUE), 2D and 3D heatmaps, Delta-T and Delta-P, humidity, security power and assets. The information can be used for server rack kW and temperature tracking and to create a computational fluid dynamics model of the airflow within the datacentre.

Using real-time data means provides the digital twin with a real-time view of the data centre’s thermal performance and comparison between the actual design and true performance of the data centre. The model therefore allows for more efficient capacity planning and server utilisation. Changes to the data centre power train and configuration can be easily modelled and single points of failure identified.

AKCP Server Cabinet Thermal Mapping Solutions

AKCP intelligent sensors can be installed within the data centre facility and specific server cabinets to track temperature and humidity levels. The AKCP thermal map sensor, is a 3-in-1 intelligent sensor that can track temperature and humidity at three points within a server cabinet; the top, middle and bottom of the rack. The sensors are used to typically monitor front air inlets, with a second set installed at the rear of the cabinet to monitor exhaust temperatures and humidity levels. The sensor sets collect accurate data for inlet and exhaust comparison.

Creating a thermal map of all the server cabinets within a datacentre can help to significantly improve PUE ratios. Thermal map data collection provides more precise monitoring and control over cooling and server temperatures. The data helps to identify areas that are being under or overcooled and allow for cooling adjustments in terms of airflow, temperature settings and fan speeds and server load utilisation.

Fixed Cable and Wireless Sensors

The AKCPro Software platform can be used to collect data via fixed IP cable and wireless sensors. The fixed cable monitoring device base units include SP1, SP2+, SP2+LCD and sensorProbeX+. For wireless monitoring, using LoRa technology, an AKCP wireless tunnel gateway server is connected to the local IP network (cabled) and can monitor up to 30 wireless sensorProbe tunnel connectors; up to 4 sensors can be connected to each of these giving a 120 sensor point system per tunnel gateway. Data is displayed on the local web UI, can be graphed, alerts such as e-mail, SNMP traps can be sent. An optional 4G cellular data modem allows for remote access and SMS notifications. The AKCPro Server software can be deployed using a combination of fixed and wireless sensors, allowing easy expansion and location of additional sensors as required, even if on a temporary basis.

Digital Twin Automation, Machine Learning and Artificial Intelligence

Digital twins can be used with Artificial Intelligence (AI) and machine learning technologies to help data center operators replicate their facilities, manage their carbon footprints, and optimise their energy usage. The monitoring and collection of data from an Environmental Monitoring system with CFD capabilities and thermal cabinet maps is an essential part of creating a digital twin model. The data provided is more granular than is typically available at a critical system sensor level for a cooling system, uninterruptible power supply, power distribution unit (PDU). With a digital twin data centre operators can simulate and model corrective and preventative improvement actions to improve operational performance and energy efficiency. They can model use cases and make recommendations.

Summary

A digital twin model is easy to deploy using the AKCP environmental monitoring solution. The modelling feature is included within the AKCPro Server software and can be easily configured using data collection from a sensorProbe+ monitoring unit and intelligent sensors. Unlike other digital twin technologies, the system is lower in cost to deploy and avoids expensive annual recurring licenses, maintenance and operational costs. The data centre digital twin feature is part of the AKPro Server Software package. Please contact our projects team for more information or book an online demo.